A department that has to be separated because of its importance in our production is quality assurance/quality control.

In LOUKAS, we give the necessary attention not only on defect prevention but also focusing on defect identification. Our goal is to reach the maximum of its capabilities to prevent problems that may occur.

Our laboratories offer a lot of services and information to our customers because engineering is the field that has to find the answers when obstacles appear.

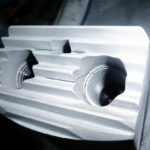

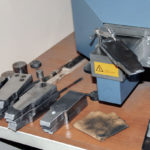

Every technique is in our spectrum and services such us NDT testing, chemical analysis, hardness measurements, roughness test, mechanical tests, penetrant fluid, magnetic particle, ultrasonic tests, balancing, technical blueprint measurements.

All these are combined in order to collect, evaluate, analyze the data to give you the whole picture for failure causes.

Anything could be tailored to the requirements of specific projects and involves a combination of the following techniques.

Last but not least, quality control engineers participate in all intermediate repair stages-quality assurance by checking dimensions or possible defects.