When you demand/ expect/ require a solution to the most urgent cases and time does not allow to extract your spare parts, we can intervene with in situ techniques.

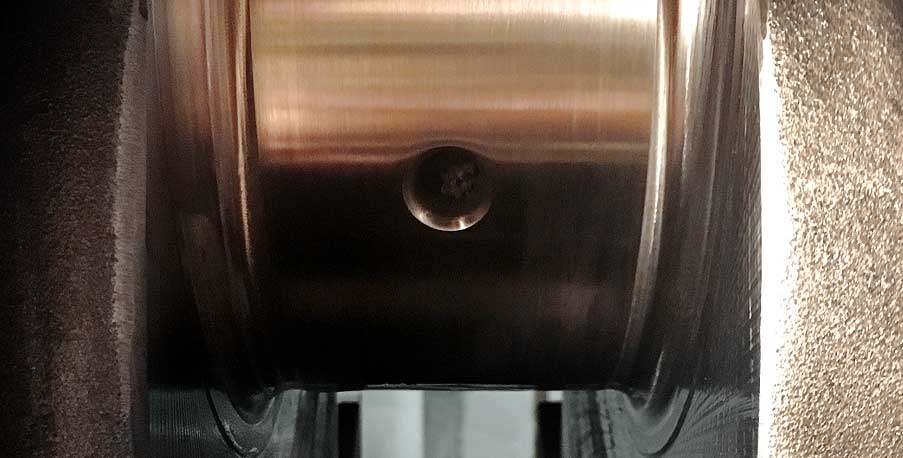

Whenever a crankshaft requires immediate recondition, some steps are not necessary, such as rebuilding or the straightening on our premises. LOUKAS boarding team can carry out the hard work of grinding/straightening/magnetic particle tests and so on/reports before and after on board with success. Crankshafts journals and radials acquire many good operational hours without any limitation.

One of the most significant advantages is the allignment and the welding procedures that we can follow to overcome any problem that may occur.

Last but not least, we should mention the fact that metal stitching techniques are another action that can carry through with great success when it is most preferable than welding.

All the technicals/technicians are able to operate 24/7/365 throughout the year on board and they are qualified and certified to carry out the work with agility and precision. We are capable of applying cost-effective solutions for minimizing downtime and eliminating costs.